Desktop Weld Optimization Software

Desktop Weld Optimization Software

for automated welding

Apps

OSLW

ISOSPOT-2D

ISO-2D

SPOT-3D

ISOEDGE

ISO-3D

ISO-2.5D

WELD-3D

YAG

HAZTEMP

ISOSPOT-3D

ISO3D.GAUSS

WELD-2.5D

WELD-2D

FAQ general

TECHNICAL DISCUSSION-1

TECHNICAL DISCUSSION-2

SmartWeld SLIDES

Sensitivity Parameters

METALS & ALLOYS

ETE Table

PUBLICATIONS

LINKS

DEFINITIONS

SmartWeld HOME

The SPOT-3D Application

Procedure Development for Spot Welding

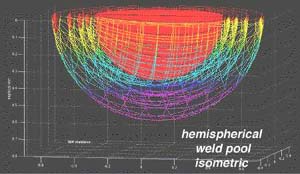

SPOT-3D is a general purpose application for computing optimal pulse parameters for spot welds where 3 dimensional (3D) heat flow predominates.

The user specifies the required weld pool dimension and SPOT-3D calculates the pulse energy and pulse duration combinations (i.e. procedure) that will produce the weld in the chosen metal or alloy.

The model is based on the continuous point source solution to the conduction heat flow equation. SPOT-3D can be used for resistance welding, pulse arc welding, laser spot welding, and other short duration processes where melting occurs very rapidly. SPOT-3D calculates the weld dimensions, pulse energy, peak power, pulse duration and several quality parameters including melting efficiency, temperature sensitivity, and peak power sensitivity .

SPOT-3D will automatically recommend a weld procedure to minimize heat input. The user can also use the mouse to query the model for many other parameter combinations. To display the resulting temperature contours, the chosen procedure is easily input directly into ISOSPOT-3D for additional analysis.

SPOT-3D currently can be used for 19 metals and alloys: 304, 15-5PH, and17-4PH stainless steels, 1018, HY80, and HY130 steels, Hastelloy C4, C22, and B2, Kovar, 1100 and 6061 Aluminum, Ti-6Al-4V, Inconel 625, and 718, Nickel 200, 110 Copper, Tin, and Molybdenum.